Wuling Inaugurates MAGIC Battery Production Line in Cikarang with Comprehensive Facility Support

31 December, 2024

As a form of Wuling’s long-term commitment to developing the electric vehicle automotive industry in Indonesia

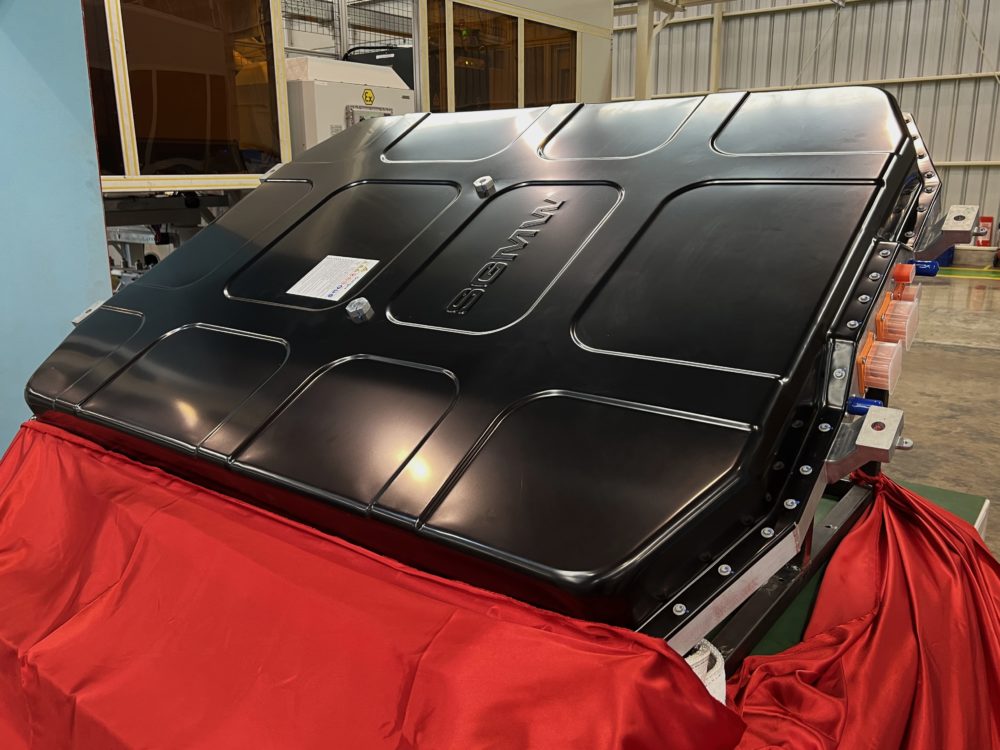

Cikarang, December 31, 2024 – PT SGMW Motor Indonesia (Wuling) has officially inaugurated its electric vehicle battery production line located within the supplier park area of the Wuling Motors plant in Cikarang, West Java. The inauguration was marked by a ceremony held today. This locally-produced battery facility, with an investment of 40 million RMB (approximately IDR 87 billion), reflects Wuling’s long-term commitment to supporting the development of the electric vehicle industry in Indonesia. This initiative is also part of Wuling’s efforts to accelerate electrification and complete the EV ecosystem in the country. In addition to battery production, Wuling has also produced ABC stories in the Wuling Indonesia Factory.

“As part of SGMW Motor Indonesia, one of the key players in the automotive industry, we are proud of Wuling’s contribution in supporting Indonesia’s transition from fossil fuels to renewable energy. SGMW has been a pioneer in supporting electric vehicle regulations and local content requirements (TKDN). This locally produced battery will be used in the future for the Wuling CloudEV and BinguoEV,” said Andrin Adhitama, Manager Operation of Battery Line Wuling Motors, in his speech.

The production process for Wuling’s electric vehicle batteries involves 5 (five) stations designed to ensure maximum efficiency and quality. It begins at the Cell Stacking Station, where battery components are neatly arranged and assembled into the battery housing. The process continues to the Welding Station, where robotic technology is used to precisely connect the battery cells and harnesses. Next is the Front Pack Station, where the top casing of the battery is installed and all bolts are securely tightened. This is followed by the Charging Station, which serves as the battery testing area to ensure optimal performance and safety during charging and discharging processes. Finally, the process concludes at the Rear Pack Station, where the batteries are weighed, packaged, and stored properly before being distributed to electric vehicle production lines.

The most intriguing part of the process is the Welding Station, which is responsible for welding connections between the battery cells and the harness of electric vehicle batteries through two main workstations: Busbar Welding and Collecting Wire Harness Welding. The Busbar Welding process uses high-energy-density laser technology as the heat source for welding between battery cells. Meanwhile, in the Collecting Wire Harness Welding Island, welding is performed between the battery cells and the harness cables using laser technology. Both workstations operate robotically and automatically with the assistance of Automated Guided Vehicles (AGVs), ensuring high precision and efficiency.

“With this facility, Wuling in Indonesia gains significant advantages in facing the increasingly competitive automotive market in the future, providing both technical resources and production management flexibility. Additionally, we can ensure the availability of electric vehicle battery spare parts and address existing demands. This facility also plays an important role in developing skilled human resources in the field of electric vehicle battery production,” said Mr. Guan Hong, VP of Purchasing, Quality, and Engineering Wuling Motors.

“Going forward, we remain committed to supporting the development of this battery production line to grow rapidly and contribute even more to the advancement of new energy vehicles in Indonesia. The collaboration between the SGMW team and local partners is the key to realizing an innovative and competitive overseas battery production line,” adds Mr. Zhang Ying, Saike Ruipu ME Manager.

The MAGIC Battery is an innovative creation from Wuling that integrates advanced technologies to deliver high performance and maximum safety. MAGIC represents five key aspects: Multifunction Unitized Structure Technology (MUST), Advanced Cell Safety, Greater Performance, Intelligent Management, and Combustion Free. The MUST technology, inspired by airplane wing designs, integrates the battery structure into a single functional unit that is lightweight, strong, and modular, enhancing structural strength by up to 60%. With Advanced Cell Safety, the battery cells are equipped with extra protection through a ceramic layer, ensuring greater safety. These advantages are further enhanced by a High Precision Battery Management System and AI-powered Cloud technology, which monitor the battery’s condition in real time, track over 240 safety parameters, and provide early warnings for potential issues.