How Car Hydraulic Brakes Work and Its Components

3 May, 2022

Brakes are one of the most important components of a vehicle. This component serves to hold the speed so that the vehicle can slow down or even stop. In motor vehicles, there are three types of brakes, namely mechanical brakes, air brakes and hydraulic brakes.

In this article we will discuss hydraulic brakes -what they actually are and how they work.

Understanding Hydraulic Brakes

Hydraulic brakes are a type of braking system that uses oil pressure from the brake lever to push the piston. To operate it, the hydraulic brake is quite easy to use because it only requires one finger. This advantage certainly makes the braking system easier to do and avoid your hands getting tired quickly. This system is certainly also very helpful, especially when you are driving on rocky or steep terrain.

The way the car works is based on Pascal’s law where the fluid material is used to transmit the braking force from the brake pedal. Although it is easier to use, this system also has drawbacks, especially in terms of maintenance. Vehicle owners must check the oil regularly and require special tools to fill brake fluid. This makes you need to routinely carry out hydraulic brake maintenance at the workshop.

For more details about the advantages and disadvantages of hydraulic brakes, pay attention to the points below:

1. Advantages of Hydraulic Brakes:

- Does not experience expansion because it uses fluid instead of wire cables

- Maximum braking power or more grip

- Does not make annoying noise when braking

2. Disadvantages of Hydraulic Brakes:

- The components use are more complex

- If there is a leak in the fluid, it has the potential to damage the car components because it has acidic properties

How Do Car Hydraulic Brakes Work?

The way hydraulic brakes work is definitely different from a mechanical braking system that still uses wires. In the hydraulic system, the braking system uses fluid. Not only that, the model of the pedals on the hydraulic brakes is also different.

The way this system works begins when the driver steps on the brake pedal. In this section, the brake pedal is connected directly to the piston in the master cylinder. When the brake pedal is pressed, the brake lever will push the piston to enter the master cylinder.

The piston is pushed and will make the space in front of the piston smaller. Not only that, the push can also cause the reservoir channel to be closed. In this way, the fluid in front of the piston will be pushed out through the main channel through the brake lines. Furthermore, the pressure will be transmitted to all braking actuators with the same magnitude.

When the fluid pressure has reached the wheel cylinder, the pressurized brake fluid will move the piston in the wheel cylinder to press the brake lining. It is at this stage that the hydraulic brake working process occurs.

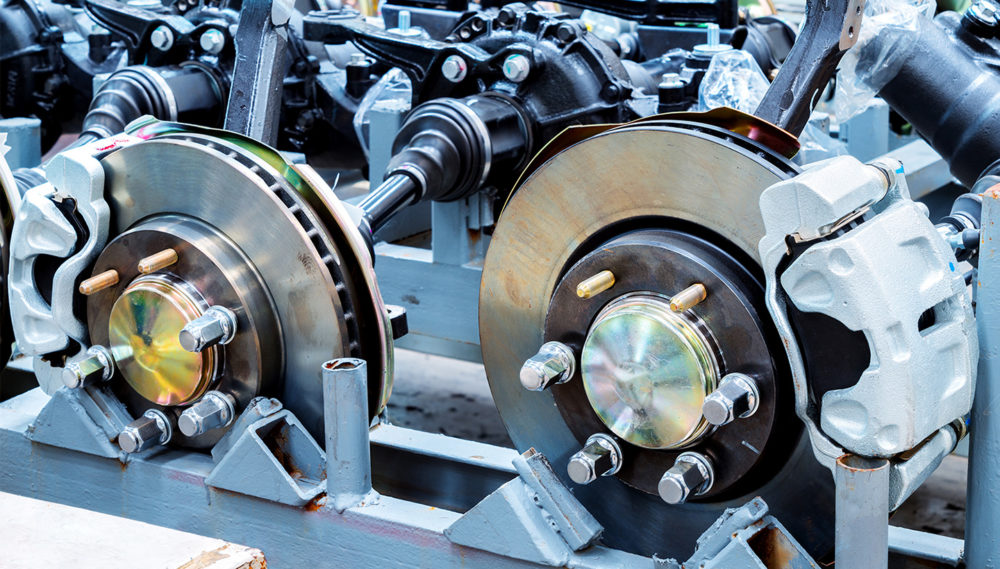

Hydraulic Brake Components

In the process of the system working, the hydraulic brake consists of various components that are interconnected with each other. There are at least 5 main components in the hydraulic braking system, including:

1. Brake Pedal/Brake Lever

The brake pedal or brake lever is also known as an input device as it is used to determine when the brakes will be activated and deactivated. In short, when the brake pedal is pressed, the brake will activate. In this case, the pedal is in charge of entering the pressure from the driver so that the brake hydraulic system can move.

2. Master Cylinder

The master cylinder is a hydraulic brake component that functions to convert mechanical movement into hydraulic pressure. This conversion is useful because the working principle of this hydraulic system is to use pressure from the fluid. Furthermore, the motion energy from the pedal will be transferred to hydraulic pressure by the master cylinder.

The master cylinder itself consists of a tube and a piston. The piston in this section is connected to the brake pedal which will then move back and forth in the tube. This movement of the piston will affect the space in the tube so that if there is fluid in the tube, the pressure will change following the movement of the piston.

3. Reservoir Tank

Reservoir tank is a component that functions to store brake fluid or fluid reserves to be used as a power supplier. The way it works is to avoid the risk of catching a cold which causes the brakes to fail.

‘Catching a cold’ itself is a term to refer to where there is air that enters the hydraulic system. When the air is compressed, the fluid pressure will increase, causing the brakes to deflate when pressed.

4. Hydraulic Pipe

Hydraulic pipe or hose is a component that functions as a place for fluid or pressurized brake fluid to flow. The hydraulic fluid pressure is usually high enough that this hydraulic pipe must be made of special materials.

In the braking system, there are usually two types of pipes, namely metal pipes and elastic pipes. However, in the majority, these hydraulic pipes are made of metal so they are not easily bent because the fluid pressure in the hose is quite high.

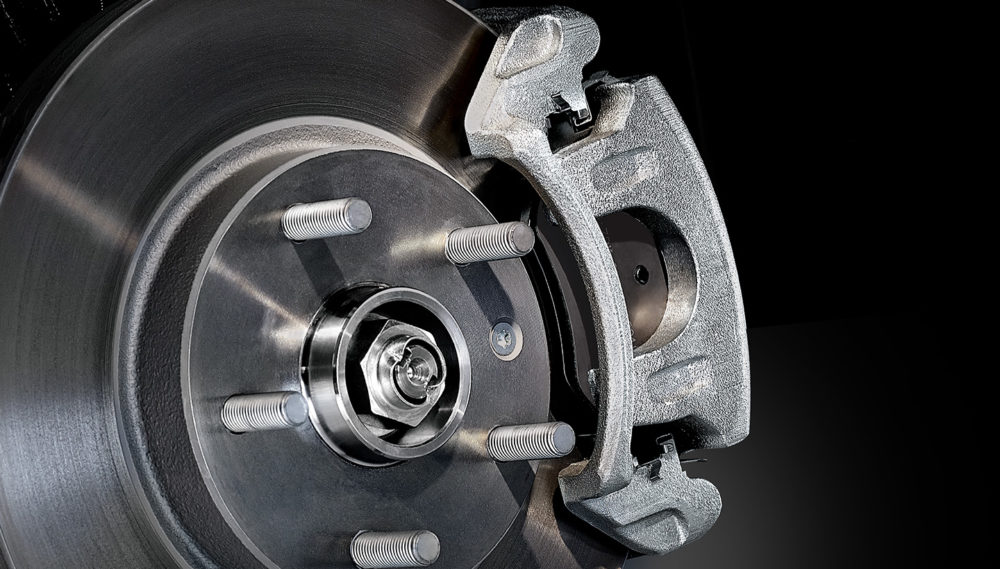

5. Caliper / Brake Actuator

The brake caliper or actuator functions to convert the pressurized fluid energy back into a form of mechanical movement. This is so that energy can be used to move the brake pads so that they can press the brake disc.

Basically, almost all car braking systems today use hydraulic principles as their driving force. This type of braking system is easier to use so as to provide maximum safety.

Even so, you need to regularly maintain this hydraulic brake system so that all its components can work optimally. In this way, the braking process can also run more optimally. But most importantly, before starting to drive on the road, make sure you understand how the hydraulic brake system works!