Car Disc Brake Components 101

31 March, 2021

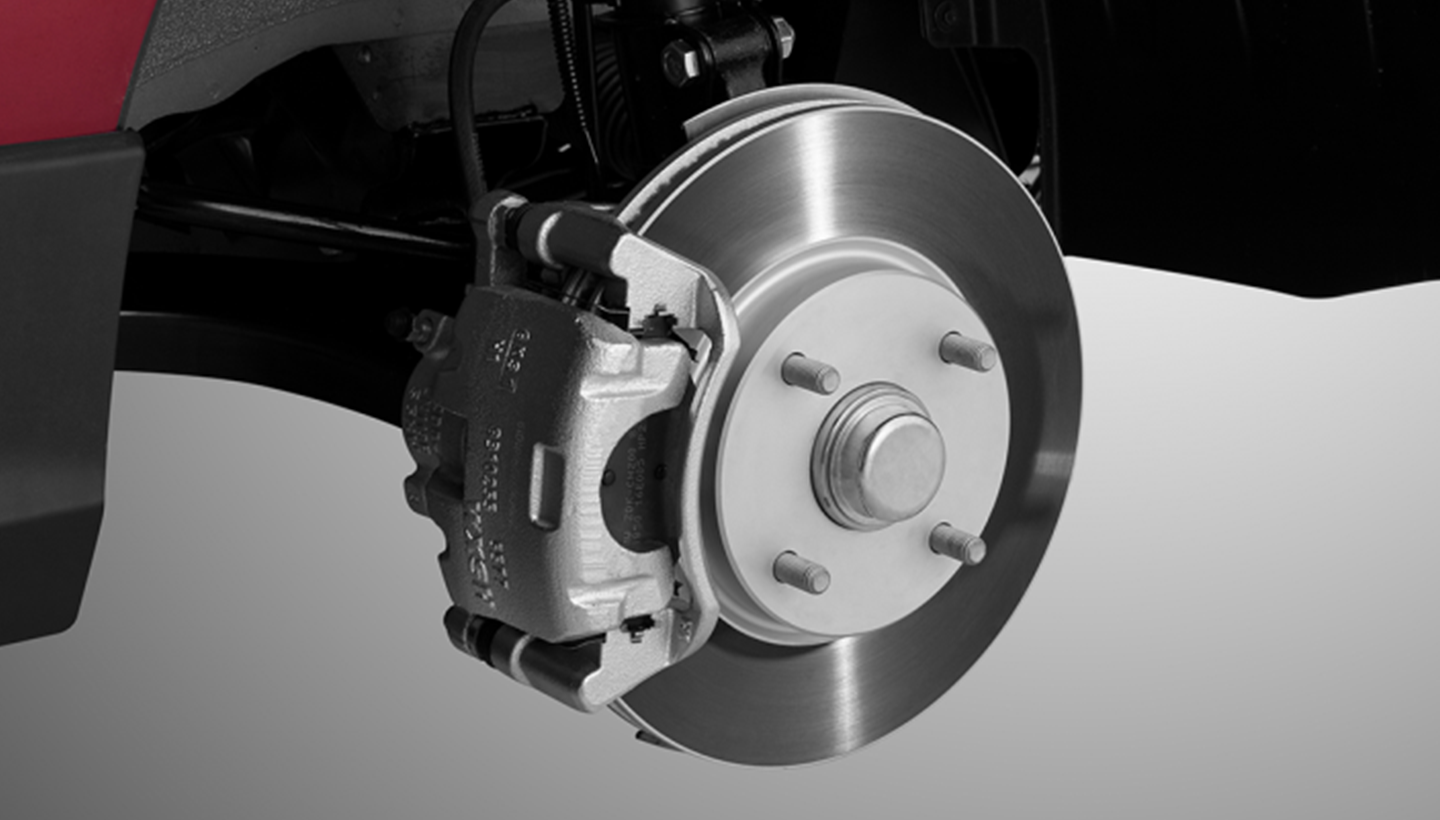

Disc brakes or disc brakes are a car braking system that utilizes additional components in the form of a disc rotor or disc clamped by two brake pads to slow down the tire rotation.

Car disc brakes have better heat radiation and when the disc is exposed to water, it dries pretty quickly. The disc brake design is also excellent. At least there are some components of disc brakes and how they work that need to be known.

Disc Brake Components

1. Brake Calipers

Brake calipers or calipers are an essential component in disc brakes in cars. Calipers will perform a mechanical movement to clamp the brake lining on the disc. Calipers are also often referred to as brake pads and piston brakes.

The brake calipers will work using hydraulic pressure generated from the change in brake fluid pressure that enters through the brake hose or cable. You need to know at least two types of brake calipers, namely floating and fixed calipers.

Floating Caliper is one of the brake calipers whose position is in the brake support caliper section. This type of caliper will later shift and move to the left or right. In floating calipers, the brake piston is only available for one side. When the piston moves, the car pushes the disc brake pads. The other side will clamp the brake lining next to it.

A fixed caliper is a caliper whose position is integrated with the brake support caliper and this keeps the caliper still and will work to suppress the brake pads, namely the brake piston only.

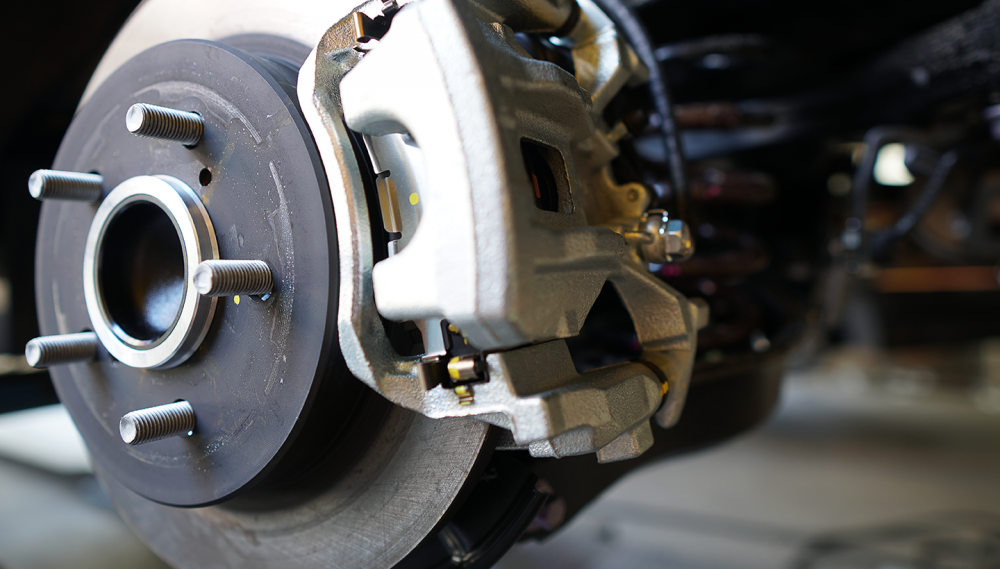

2. Brake Shoes

Brake pads or brake pads are one of the components in disc brakes that emphasize the disc portion to provide friction to stop the rotation of the disc brake.

Make sure you choose brake pads made by well-known companies so that you can get quality brake pads with good materials. The materials for brake pads come from ceramics, asbestos, zither and semi-metal.

The choice of brake lining material can be a consideration for you in buying brake pads. The brake pads’ work is hefty because they have to do a large friction force, and the brake pads must be able to stop the rotation of the disc optimally.

The better quality of the brake pads material, the higher the price will be, so brake pads for sports cars have a very high price.

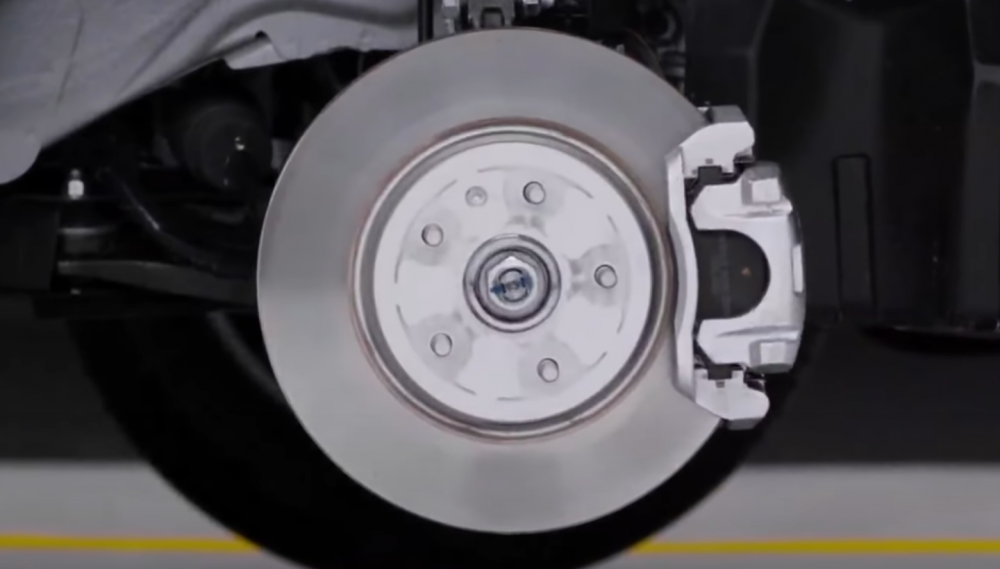

3. Disc plate

Disc or disc brakes are disc brake components that will connect directly to the axle axles, which will rotate by following the wheels’ rotation. This disc brake component becomes a core part of car disc brakes.

The disc will function as a medium that will be clamped or pressed by the brake pads so that the braking process appears on the car. The material usually used in disc discs is cast iron.

Several dishes are made of ceramic matrix composite or carbon composite, and this material is usually used to produce high-speed luxury car dishes. Carbon and ceramic composite materials can release heat faster than cast iron.

There are two types of popular car discs in Indonesia: solid discs with ventilated discs. The solid disc is a type that has a very solid shape with a high level of thickness, and there are holes around the disc. However, the braking power is excellent because the grip is firm.

A ventilated disc is a disc type with a unique design because holes in the disc and holes are made to accelerate the cooling process to release heat more quickly.

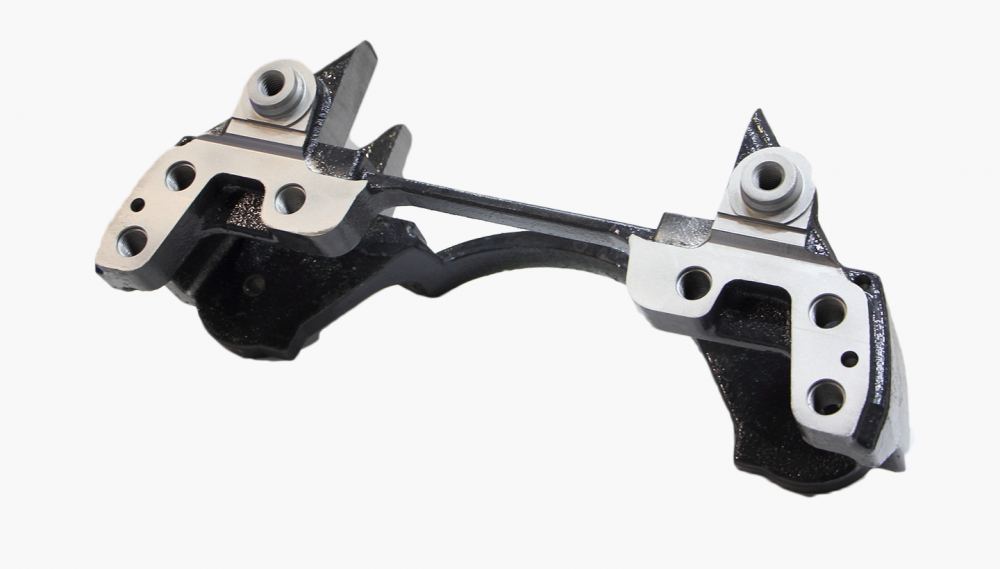

4. Caliper Bracket

The caliper bracket cannot be removed from the car disc brake unit because the caliper bracket is used to attach the caliper, which will keep the caliper in place will not move.

5. Piston Brake

The piston brake is positioned inside the caliper, shaped like a tube with a groove end. The piston brake functions to press or push the brake lining to the disc so that the wheel rotation can be lowered or stopped.

6. Piston Seal

The piston seal is one part of the piston made of brake fluid, so it has heat resistance properties. The piston seal functions to prevent brake fluid leakage that can flow when the brake lever is pressed. The piston seal can help pull the piston back and forth during the braking process.

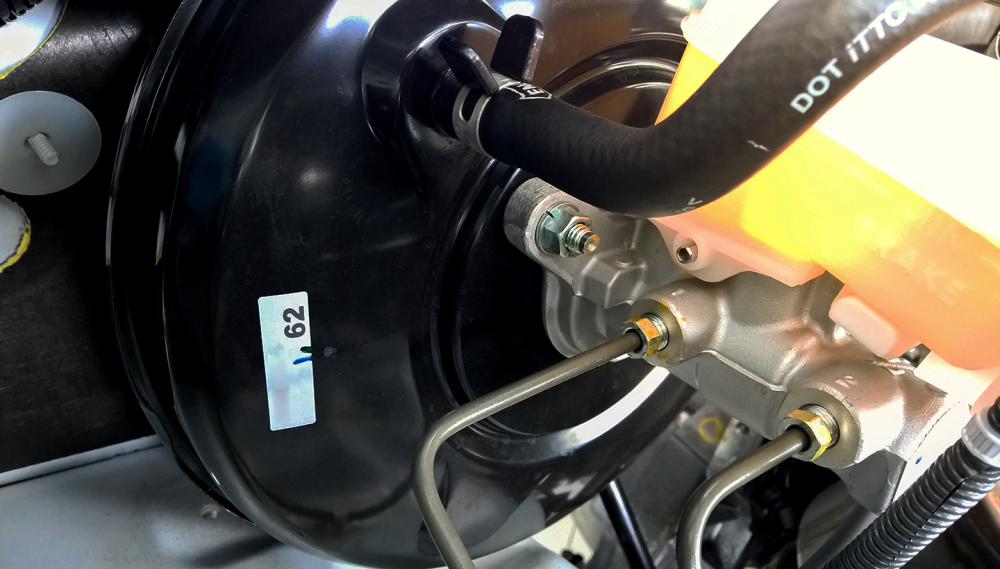

7. Master Cylinder

The master cylinder will work by converting the mechanical movement of the brake pedal into hydraulic pressure. The master cylinder has a system component directly connected to the brake pedal. From the piston, the pressure on the fluid or brake fluid is applied. 2 types of master cylinders are popular in Indonesia, namely the tandem type master cylinder with the single type.

The tandem type is a master cylinder with two outlet hoses and two pistons that can separate the control of the rear wheels from the front wheels. If one piston is not working correctly, the other piston will continue to brake, so it will be safe to use.

The single type is the master cylinder which carries only one outlet hose and one piston. This one part has the same function, namely controlling all four wheels properly. In terms of safety, the single type is lacking because when a breakdown occurs, and the condition worsens, the braking system will be very disturbed.

8. Reservoir Tank

The reservoir tank is a disc brake component that functions to accommodate extra brake fluid, usually attached to the master cylinder. In the tube, a sensor has been installed to detect the level of brake fluid volume level.

9. Brake Fluid

Under normal conditions, the brake fluid volume should not decrease, and when it is reduced, there is a leak. The brake fluid will also not perform optimally if the condition is dirty.

Brake fluid or brake fluid functions as a medium that can generate thrust from the brake pedal to the caliper. This will make the brake pads clamp down on the disc.

Brake fluid is divided into several specifications based on each type’s boiling point, which is made clear by the standardization on the part of the package marked or marked with dot 3 and dot 4.

Car owners must pay attention to the brake fluid’s specifications to be used in the car so that the braking process will work properly and precisely.

10. Brake Booster

The brake booster is a disc brake component made of a membrane connected to the intake manifold. The brake booster serves as an assist that can help reduce the force of pressing the brake pedal without reducing braking power.

The brake booster can also double the braking energy when the driver is doing the braking process. This makes the rider not require a lot of power in the braking process. The driver will feel light when stepping on the brake pedal with the brake booster component’s help.

11. Hydraulic Hose

The hydraulic hose is one of the core components in disc brakes because it distributes brake fluid to various brake calipers with ongoing hydraulic pressure.

12. Brake Pedals

The brake pedal is a disc brake component that functions to help activate a vehicle’s braking system. In general, brake pedals are made with extended arms or levers and match the driver’s braking needs.

Disc Brake Function

The function of disc brakes in a car is to control the vehicle’s speed so that it can run and stop according to the wishes of the driver. Disc brakes will make the driver safer in controlling the car.

Most cars used braking systems with drum brakes or drum brakes, but now many cars are equipped with disc brakes. Disc brakes have been widely used in various types of cars, be it on the car’s front or rear.

Car manufacturers have deliberately changed the braking system to disc brakes because they are safer and can make the car stable, even when used at high speeds. The process of stopping a car is more optimal when using disc brakes than drum or drum brakes.

To stop the car, of course, you don’t need a long distance as a square, and by using disc brakes, all the legs of the car can stop quickly. In other words, disc brakes can shorten the braking distance. With disc brakes, the safety of the drivers will be safer in the car.

Using a car that has used disc brakes, you will be calm and more secure.

Advantages of Disc Brakes

1. Better Cooling Brake System

The friction that occurs on a brake can indeed cause heat, disturbing the braking system of the car. However, disc brakes have an open construction, and this will cause the heat generated to be released directly into the air, which flows directly around the brakes.

The disc brakes’ temperature is more stable because the brake cooling process will work when the car is moving.

2. No Sound When Braking

In general, the noise that occurs during the braking process is usually caused by hardened brake pads. With hardened brake pads, it can cause the brake pads’ quality to be less good, which can also arise due to the heat factor.

When brake pads are continuously exposed to excessive heat, the brake pads’ condition will harden and when the brake pads are set, their texture will change to resemble metal. When it forms like metal, the car that brakes will make a sound.

3. Easy Maintenance

The components used in the disc brake braking system are brake pads, and the drum brakes are brake shoes. The brake pads are usually attached to the brake bracket in the open position. In contrast, brake shoes are generally inside the drum.

To care for disc brakes is easier than drum brake maintenance. When you want to change brake pads, you only need to open one caliper bolt and by opening one bolt, the brake pads will immediately open or come off. To open the drum brake, you have to remove the drum and then remove the brake shoes using specific tools.

4. Constant Braking Force Even When Exposed To Water

When using a car through a puddle, the dish will be immediately exposed to water. Even though it is directly exposed to water, the braking force will not change because it will drain the water out instantly due to the centrifugal force from the disc’s rotation.

Unlike the case with the drum brake’s working system, because the water that enters the drum will make the braking system or the braking force decrease. Water that enters the drum will be more challenging to get out, disturbing the braking system.

5. Evenly Braking Pressure on All Brake Pads

Disc brakes will not experience additional braking force, and this will make the braking evenly distributed so that no one of the wheels will have a greater braking force. This condition prevents the car’s wheels from being pulled in one direction, either left or right, during the braking process.

Disadvantages of Disc Brakes

1. Disc Brakes Cannot Withstand Heavy Loads

Brake pads do have a limited area, and this makes the rubbing media also limited. This condition makes braking power limited. With the limitations experienced, braking will not support large loads.

Disc brakes require a large braking force if you want to produce better braking quality. This is one of the reasons why cars with high loads use disc brakes in their braking system.

2. Requires Additional Components to Enlarge the Style

When disc brakes require greater braking force, it is necessary to add a brake booster component. With the brake booster component, the car can brake with great force.

The brake booster is useful for increasing the braking force to significantly ease drivers who step on the brake pedal.

3. Wheel Rims Get Dirty Easier

Disc brakes can indeed cause the rims to get dirty or dusty more efficiently, this is due to the open construction of the disc brakes, and this condition will make dust from the brake pads stick to the wheel rims. For beginner drivers and new to owning a car, they must regularly clean the wheel rims so that the car looks fantastic.

That’s a complete discussion of how the car’s disc brake components work & function. Hopefully, the complete discussion above can be the best reference and insightful for the Wuling Family.